0102 ib0304 ib05

Stamped Grid vs Expanded Grid: Optimizing Lead-Acid Battery Manufacturing rau Nqi thiab Kev Ua Haujlwm | MINHUA Group

2025-02-21 2025

Kev Sib Piv Module (Infographic-Friendly)

1. Cov txheej txheem tseem ceeb

| Parameter | Expanded Grid | Stamped Grid |

|---|---|---|

| Khoom Prep | Molten lead → Nruam casting (0.8-2.0mm strip) | Molten lead → Nruam dov (1.2-3.0mm strip) |

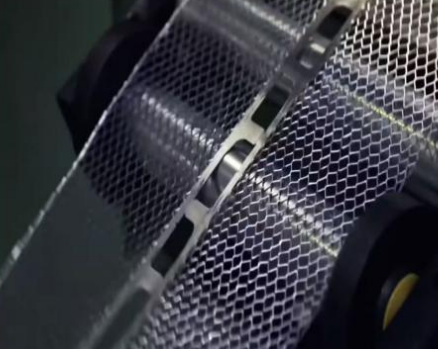

| Txoj kev tsim | Punching + Mechanical stretching (18-25m / min) | Precision stamping (300-500 strokes / min) |

| Dimensional kam rau ua | ± 0.2 hli | ± 0.05 hli (pwm-nyob) |

| Cov cuab yeej tseem ceeb | Expanding tshuab | Progressive tuag stamping xovxwm |

Qhov txawv tseem ceeb:

- Stamped daim phiaj cia siab rau cov pwm ua haujlwm siab (± 0.05mm) rau cov geometry nyuaj; Cov kab sib txuas nthuav dav tseem ceeb ua kom yooj yim nrog qis dua.

2. Kev ntsuas kev ua haujlwm

2.1 Mechanical Strength (ASTM E8 Txuj)

| Test Parameter | Expanded Grid | Stamped Grid |

|---|---|---|

| Tensile zog | 38-42 MPa | 55-62 MPa |

| Elongation ntawm Break | 15-18% | 8-12% |

| Fatigue Life (Cycles) | 5,000 | 8,000+ |

ASTM E8 Kev Ua Raws Cai:

- Ntsuas qhov ntev: 4D (E8) lossis 5D (E8M) rau kev npaj cov qauv zoo ib yam.

- Tus nqi lim: 0.015 ± 0.006 mm / mm / min (kaw-loop tswj).

2.2 Production Economics (USD / 10k units)

| Qeb Nqi | Expanded Grid | Stamped Grid |

|---|---|---|

| Tus nqi cuab yeej | 0 | 700-1,200 Nws |

| Tus nqi zog | 120 | 180 |

| Cov khoom siv rov ua dua tshiab | 25 | 85 |

| Tus nqi tag nrho | 145 | 965+ ib |

Ntsiab kev pom:

- Stamped grids incur 75% tooling tus nqi, siv tau tsuas yog rau ntau lawm; nthuav daim phiaj txo cov nqi seem los ntawm 70%, zoo tagnrho rau cov nqi-rhiab heev.

Daim Ntawv Qhia Kev Lag Luam Daim Ntawv Thov

3. Cov xwm txheej pom zoo

| Technology | Daim ntawv thov |

|---|---|

| Expanded Grid | ? Automotive SLI roj teeb (> 100k units / hli) |

| ? Nqi-sensitive ESS tej yaam num (40% qis CAPEX) | |

| ? Standardized daim phiaj tsim (pob zeb diamond / duab plaub) | |

| Stamped Grid | ? Pib-nres / sib sib zog nqus roj teeb (> 1,200 cycles, ib IEC 61427) |

| ? Kev cai geometries (honeycomb / radial daim phiaj) | |

| ? High-precision kam rau ua (thickness variation |

Kev soj ntsuam scenario:

- Pib-Stop Systems: Stamped grids ' tensile lub zog (55-62 MPa) thiab qaug zog lub neej (8,000+ cycles) ua tau raws li qhov xav tau ntau zaus.

- ESS Projects: Nthuav daim phiaj 'tag nrho cov nqi (145 USD / 10k units) suits CAPEX-sensitive deployments, nrog standardized designs enabling scalability.

Innovation Trends & References

- Advanced Grid Geometry: Stamped daim phiaj pab kom 18% siab dua cov khoom thauj khoom ntawm cov qauv honeycomb, validated nyob rau hauv daim phiaj-forming ESS tej yaam num (xws li, Xinjiang Bazhou Shared ESS).

- Pwm Technology: GREE's ± 0.001mm precision pwm thiab 380-strokes / min stamping ceev tau nrawm rau kev txais yuav hauv cov roj teeb hwm EV.

Tshaj 95% Cov neeg siv khoom zoo siab!

Zoo siab txais tos txhua tus tshiab thiab qub cov neeg siv khoom tuaj xyuas peb lub tuam txhab. Pab neeg muag khoom tshaj lij los muab kev teb sai thiab kev pabcuam zoo. Peb ib txwm nyob ntawm koj qhov kev pabcuam yog tias koj muaj kev xav tau. Nrhiav rau pem hauv ntej rau peb lub neej yav tom ntej kev sib koom tes thiab kev sib raug zoo!

Kawm ntxiv